Introduction: What is Lightning Arrester?

A Lightning Arrester is a device used to protect a variety of electrical equipment and systems from the effects of lightning. This device uses a technology called Corona discharge.

Corona Discharge Technology uses the mechanism of discharge of high voltage in a short period by ionization of nearby air ions. A typical lightning arrester consists of a high-voltage terminal at the top, followed by a low-voltage terminal at the ground.

We at Renown Power produce a Home Lightning Protection System. As per standard definition, a system of lightning protection for homes uses a combination of highly conductive copper and aluminum alloys. This renders a low impedance path to the ground that saves the electrical system from fault current damage.

Types of a Lightning Arrester

Let us discuss some types of lightning arresters. The choice of lightning arrester depends upon the following factors:

- Voltage

- Current

- Reliability

- Space available for installation, etc

Heeding these above factors, there are twelve types of lightning arresters.

- Rod Gap Arrester

- Sphere Gap Arrester

- Horn Gap Arrester

- Multiple-Gap Arrester

- Impulse Protective Gap Arrester

- Electrolytic Arrester

- Expulsion Type Lightning Arrester

- Valve Type Lightning Arresters

- Thyrite Lightning Arrester

- Auto valve Arrester

- Oxide Film Arrester

- Metal Oxide Lightning Arrester

Let us focus on some primary and important types of Arresters.

Rod Gap Arrester

It is one of the simplest types of Lightning Arresters. In the before-mentioned type, there is a gap between the end of the two rods. These two rods get connected to the earth and the line directly. The gap gets filled with air.

When there is a higher voltage on the line, the air ionizes, producing a spark. In this fashion, the fault current passes to the earth. The process is explicated above in the snippet. Hence, the equipment is saved from potential damage.

Sphere Gap Arrester

In such types of lightning arresters, an air gap is provided between two spheres. Here, one of the spheres is grounded, and another is connected to the line. The diagram below represents the process in detail.

There is a choking coil between the transformer and the ground, which heats up when the voltage rises. The air between the spheres heats up and tries to escape. But the corona discharge mechanism ionizes the air and the fault current passes through it. Thus, it saves potential damage to the device.

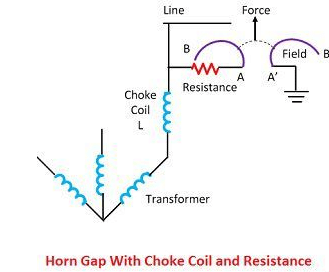

Horn Gap Arrester

This contains two horn-shaded pieces of metal. These two are separated by a small air gap and connected in a shunt between each conductor and earth. The distance between the two electrodes is optimum. This distance is filled with air that ionizes on fault current passage.

Hence, the fault current is passed to the earth, and the inherent damage is stopped.

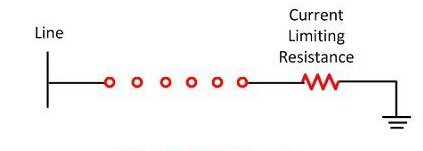

Multiple Gap Arrester

The schematic diagram above shows the details in brief. It consists of a small series of insulated through an air gap. The number of gaps depends upon the voltage. The gaps protect the device through the corona discharge. In it, air ionizes, and fault current passes through the ground. A resistor is added to stop the fault current even further.

Electrolytic Arrester

It has a high discharge capacity. It operates on the basic principles of an electrolytic cell. Expressly, here aluminum hydroxide deposits on the aluminum plates. The plate acts as a high resistor to a low voltage value and vice versa for a critical value.

A voltage of more than 400 volts punctures the impedance. Hence the fault current passes to the ground.

Thyrite Lightning Arrester

These types of lightning arresters are commonly used for extremely high voltage conditions. It consists of a ceramic material called Thyrite, which has a variable resistance. The resistance is inversely proportional to the voltage applied at the ends of it.

It contains a disc that is made conductive on both sides by spraying some conducting material. The disc is contained inside a translucent porcelain container. It is used as a joint in the container.

When the lightning takes place, the voltage gap is filled through the breakdown of gaps. This saves the device from implied damage.

Metal Oxide Lightning Arrester

It is also called Zinc Oxide diverter. The schematic diagram below shows the process.

These types of diverters are known as gapless surge diverters. The base material here is zinc, and the oxide manufactured is zinc oxide. It is a semiconducting material. This material is anesthetized by adding fine powders of insulating oxides.

This powder is treated and then stuffed into a disc-shaped structure. The disc is then enclosed in an earthenware housing filled with sulfur hexafluoride.

Thus, the arrester consists of a potential obstacle at the edges of zinc oxide. This potential barrier constrains the river and pathways of the current. Under normal conditions, it stops the flow of current. But when there is a potential breakage, the barrier collapses and the fault current passes to the ground.

Thus, this stops the surge from damaging any device.

Lightning Arrester for building

A lightning arrester rod is a metallic arrangement used to protect a building from lightning and its surges. The lightning arrester for buildings is made from conducting metals like copper and iron. And alloys like brass, mild steel, etc. Therefore it has high earth coverage of around 60 meters.

Lightning Arrester installation

A lightning arrester installation must use the guidelines:

- The top of the terminal should be established at least 2 meters over the area that it shields.

- Each lightning rod should be blended with at least two down conductors.

- The bend radii must be less than 20 cm.

- Down-conductors shall be placed rather at the external part of the fabrication.

- The in-house resistance should be as low as possible (say less than 10 Ohms).

- All earthing equipment for a specific structure should be interconnected.

- Minerals should be added to lower soil resistivity (say Backfill compound).

Comparison: Lightning Arrester VS Surge Arrester

The major functions of the Surge Arrester are:

- It protects the installation from inside.

- The surge protector protects the system from lightning, switching, electrical faults, and other transient voltages and surges.

While, the major functions of the Lightning Arrester are:

- It protects the system from the outside.

- Lightning arresters are mainly used for lightning strikes and associated surges.

Conclusion: How much are safety rules necessary?

As per the Institute of Electrical and Electronics Engineers (IEEE), “Surge protection has become a much more complex and important issue in recent years. The value of electronic equipment in a typical house has increased enormously. That equipment is also more vulnerable to surges produced by lightning, because it is networked with other equipment throughout, and even outside, the house. AC protection alone, the traditional approach, is totally inadequate to protect most of the equipment in a typical residence”.

Analyzing the experts’ advice, we need to follow the rules of safety.